SANYO DENKI AMERICA Assembly Facility

WE DON'T JUST ADD VALUE; WE DELIVER SOLUTIONS

At SANYO DENKI AMERICA, we provide comprehensive solutions for cooling, power, and servo systems within our ISO 9001-certified facility. Our expertise encompasses the assembly of tailored actuators, gearheads, connectors, cables, harnesses and other essential components. Additionally, we offer professional design proposals, including the development of intricate assemblies such as cabinets and fan trays.

Solutions and Capabilities

![]() DESIGN PROPOSAL

DESIGN PROPOSAL

We use our expertise and manufacturing capabilities to help you design, build, and fulfill your manufacturing needs, including mechanically intricate assemblies like power distribution units and fan trays, to meet your manufacturing and business goals.

![]() BOM CONTROL

BOM CONTROL

We provide comprehensive BOMs for Your Design Proposals. Count on us to source and secure vendors with optimal pricing and lead times, so you don't have to. We're dedicated to constantly improving BOM efficiency and processes through digital manufacturing.

![]() UPS ASSEMBLIES

UPS ASSEMBLIES

We perform local battery assembly for UPS units shipped from our Japanese factory at a UL certified facility in the United States, reducing lead times and cost. We also offer UPS customization options, including input voltage range reprogramming.

![]() 100% QC AND TESTING

100% QC AND TESTING

We guarantee your product's resilience through our reliability and failure analysis expertise. Extensive testing, whether following ISO 9001 or QSRs, covers every detail to ensure high reliability in any scenario.

|

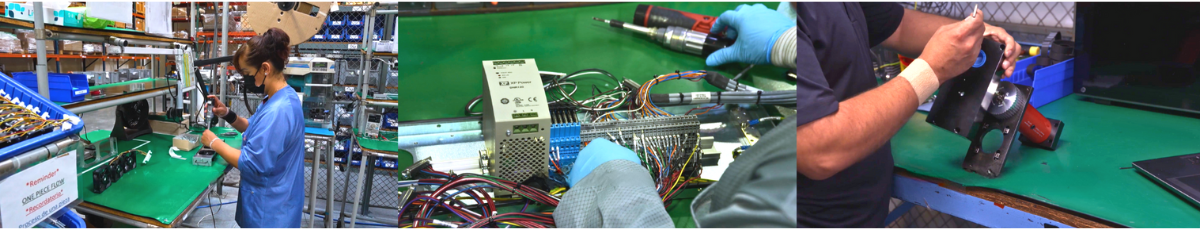

Manufacturing CapabilitiesOur team of builders takes enormous pride in the craftsmanship of their work, and are held accountable to produce error-free products that meet clients’ deadlines.

|

Customize and Value-Add

|

|---|

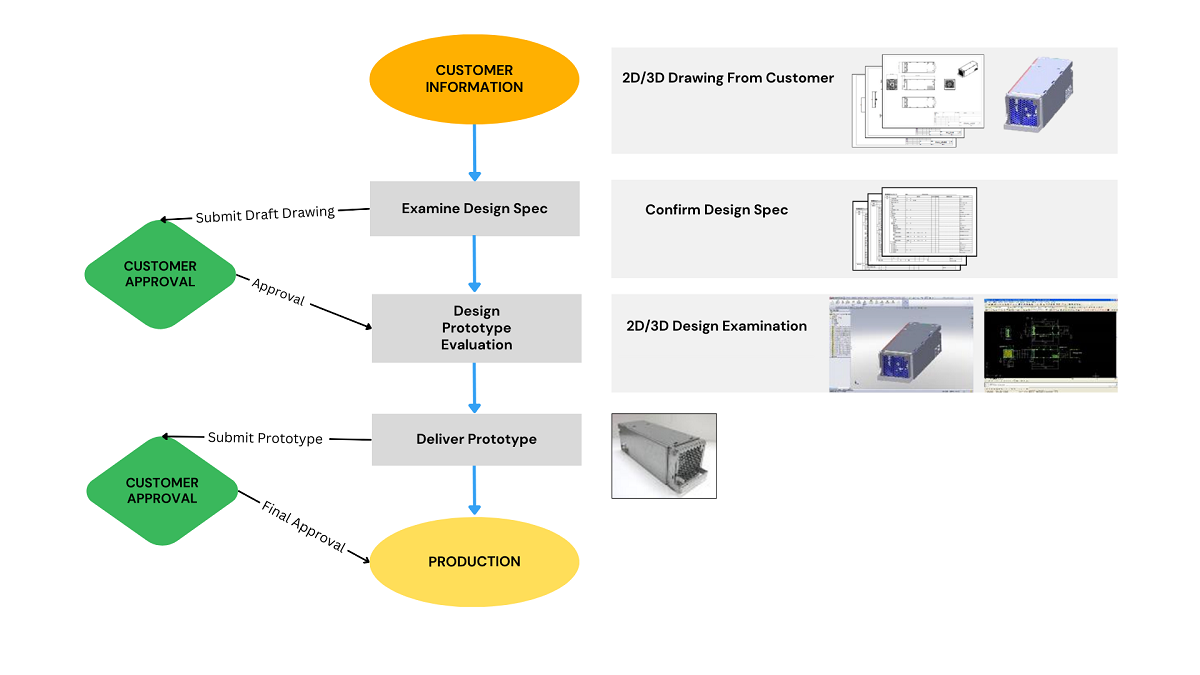

Design Process

Custom products are designed to meet customer requests. Whether parts have been specified beforehand or a production method needs to be developed, SANYO DENKI has proven processes to deliver quality products.

UL817 and ISO 9001 Certified

|

Industrial control panels are defined by the National Electrical Code (NEC) Section 409.2 as an assembly of two or more power circuit components, control circuit components, or any combination of power and control circuit components. These components are typically switches, terminal blocks, contactors, motor drives, transformers, overcurrent protective devices and the like. |

SANYO DENKI AMERICA, INC. Assembly Facility

SANYO DENKI AMERICA provides the total solution for cooling, power and servo systems.

Depending on the requirement, we assemble panels, actuators, gearheads, connectors, cables, harnesses and other peripheral parts to our product in our ISO 9001 certified factory.

Please contact your local Sales Representative for inquiries or to schedule a facility tour. We look forward to learning more about your project and how we can offer our support.

468 Amapola Avenue, Torrance, CA 90501 | TEL: (800) 905-7989 | CONTACT US

Harnesses, Cables and Other Peripherals to Cooling Fans and Servo Motors

Harnesses, Cables and Other Peripherals to Cooling Fans and Servo Motors Mechanical Components Assembly with Gearhead and Actuators

Mechanical Components Assembly with Gearhead and Actuators Electrical Assemblies with Fan Trays, Cabinets and Electric Components Mounted in Customized Sheet Metal Enclosure

Electrical Assemblies with Fan Trays, Cabinets and Electric Components Mounted in Customized Sheet Metal Enclosure Custom Cable Wiring Harnesses

Custom Cable Wiring Harnesses Measurement/Test Data Logging Service

Measurement/Test Data Logging Service Machining and Cutting Services

Machining and Cutting Services